Hopper bottom silos components

Our silos are designed for the requirements of the different commercial applications and are manufactured with the latest technology. They are carefully designed to withstand the loads due to continuous use, strong winds and heavy snowfalls.

MATERIAL

S350 GD + ZM-310 steel according to EN 10147 or EN 10326 or EN 10346

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

ZM-

0

Galvanization

THICKNESS

0.8 mm to 1.2 mm

DIMENSIONS AND GEOMETRY

- They can be supplied with a 30º, 35º, or 40º inclination

- 85mm (width) x 74mm (height) wave

- 2 side pleats for maximum resistance

ROOF STRUCTURE

MATERIAL

S350 GD + ZM-310 steel according to EN 10147 or EN 10326 or EN 10346

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

ZM-

0

Galvanization

THICKNESS

1,5 mm to 4mm

DIMENSIONS AND GEOMETRY

- Constructed with “C” beams, single or double

- Section 240 x 78 mm.

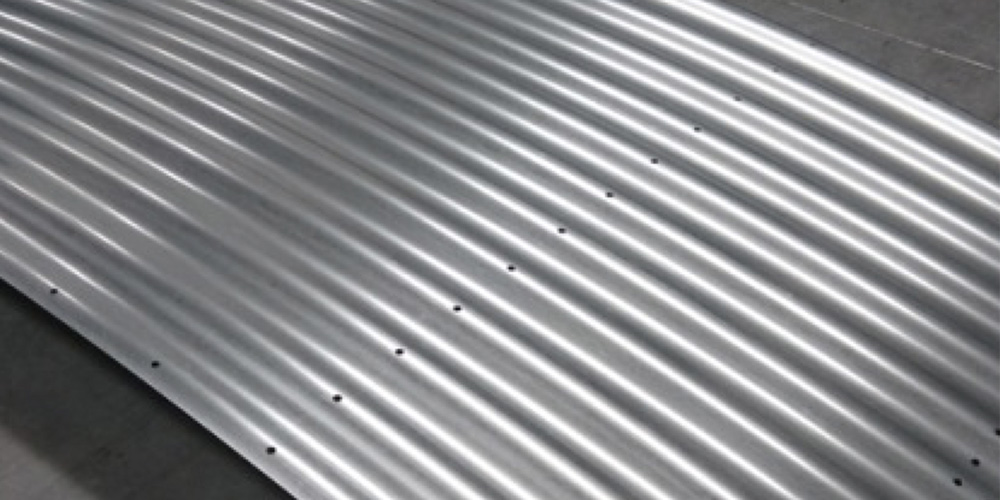

BODY SHEETS

MATERIAL

S450 GD + ZM-310 steel according to EN 10147 or EN 10326 or EN 10346

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

ZM-

0

Galvanization

THICKNESS

0,8 mm to 4,5 mm for a single body sheet

DIMENSIONS AND GEOMETRY

- 85 x 15 mm wave for an adequate material flow

- 1.105 mm effective height of body sheet

- Bolted joints design to maximize material

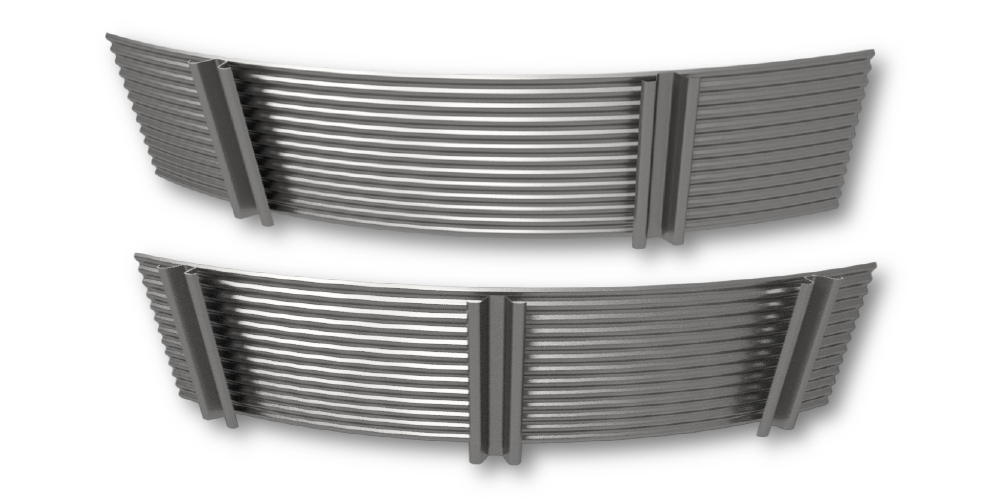

STIFFENERS

MATERIAL

S450 GD + ZM-310 steel according to EN 10147 or EN 10326 or EN 10346

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

ZM-

0

Galvanization

THICKNESS

1,5 mm to 4 mm for single stiffeners

DIMENSIONS AND GEOMETRY

- Improved load transmission through the wings

- Special design for better material use

- 2 or 3 stiffeners per body sheet

METALLIC HOPPER

MATERIAL

S450 GD + ZM-310 steel according to EN 10147 or EN 10326 or EN 10346

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

ZM-

0

Galvanization

THICKNESS

From 1,5 mm to 8 mm

DIMENSIONS AND GEOMETRY

- Hoppers can be supplied at 45º or 60º

- Layout and design as per project requirements

SUPPORTING STRUCTURE AND COMPRESSION RING

MATERIAL

Steel S275 + Hot dip galvanization according to EN 10025 y EN 1461

MECHANICAL PROPERTIES

0

Yield strength

(N / mm2)

(N / mm2)

0

Breaking load

(N / mm2)

(N / mm2)

0

Min. Elongation

(%)

(%)

Hot dip galvanized

DIMENSIONS AND GEOMETRY

- Hot rolled profiles from HEA 100 to HEA 300 as per project requirements

- Variable unloading height

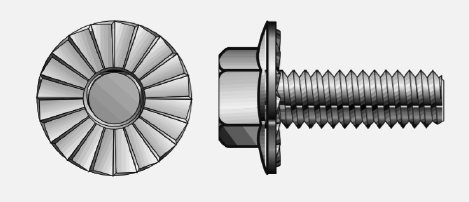

SILO BOLTING

- 8.8 and 10.9 grades

- Extra strength and extra protection against corrosion

- Serrated flange bolting for secure tightening

- Flange bolts and nuts with the integrated washer

- Supplied with EPDM gasket already inserted

- 25% greater protection than hot dip galvanized

Rust-free hours in salt chamber according to ISO 9227

0

Prado standard

0

Hot dip galvanized

0

Bi-chromed