What makes the temperature inside a silo such an important factor when ensuring the preservation of grain? In fact, almost all harmful conditions for the stored product are likely to worsen with warmer temperatures, such as the appearance of moisture, mould and fungi. In this article, Prado Silos will be explaining the function of a crucial element for many silos: the temperature and humidity control systems. Today we will review the importance of silo monitoring when it comes to maintaining the maximum added value for each stored crop.

The core mission of agriculture is to guarantee food security. For this reason, it is often said that when the farm fails, everything else follows down. After decades manufacturing silos for clients all over the world, with thousands of successful projects completed for major agricultural operators, Prado Silos is now fully dedicated to the integration of knowledge, innovation and technology as the necessary milestones to develop performance and productivity, on a high and sustainable level at the same time.

In this regard, state-of-the-art silo temperature monitoring systems and devices for real-time monitoring of different parameters, for example, represent sophisticated and evolving technologies which play a key role in the safe storage of grain crops within the time horizon desired by the agricultural operator for each project.

When analysed on a yearly basis throughout the world, grain production follows an increasing and unstoppable trend, and therefore the need for proper grain storage is also on the rise. Today, storage solutions such as silos and all associated products and technologies represent a booming industry. According to the latest data of the World Food and Agriculture Organization (FAO), world cereal production will reach 2,819 million tonnes by the end of 2023, a 0.9% increase over the previous year.

However, when looking more closely at the FAO data, we can see that approximately one-third of the grain produced globally is currently stored. Accordingly, the conservation of these stocks in adequate conditions, avoiding any loss of value, quality or nutrients, becomes critical.

On the other hand, the development of agricultural technologies has reduced the time between harvest and storage of grain from weeks to a few hours. With this in mind, it is now imperative to use the latest technologies, such as modern temperature control systems, to preserve the value of the grain stored in silos for long periods of time.

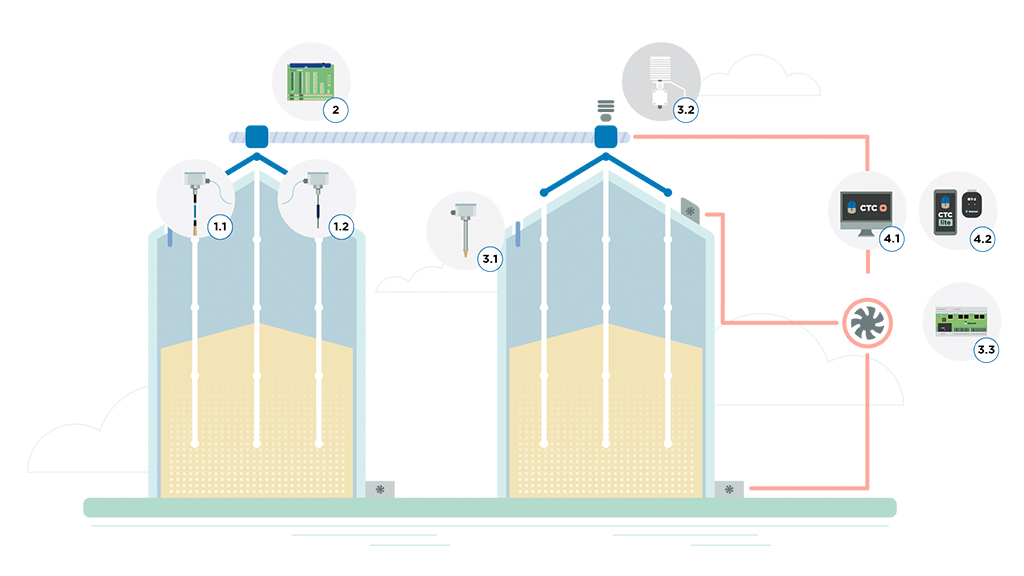

The temperature monitoring system provides real-time data on the temperature of the grain stored in the silo. With today’s new technologies, the parameters and alerts of a temperature monitoring system can be easily adjusted from any portable device. Other information such as humidity, condensation, CO2 concentration, ventilation systems management, etc., can also be monitored. This means that any variation away from the right conditions required for the grain is automatically detected, providing the proper information to apply a quick and localized solution for avoiding any loss of quality in the stored grain.

Modern silos used today in farming operations all over the world, such as those manufactured by Prado Silos on their state-of-the-art automated production lines, are made from high-quality steel profiles, with a galvanized coating designed for weather protection and to extend their useful life. Each silo satisfies specific needs concerning its final location, climatic conditions and stored product, making temperature control systems essential in today’s agricultural projects.

It may not seem like it, but the increase in temperature of the steel sheet caused by the sun’s heat is very superficial and does not affect the bulk of the grain to any great extent. However, the internal temperature variation is in fact what can really harm the product, as it activates the biological process of the grain and allows insects or fungi to reproduce: we must remember that grain is a living organism, with its metabolic and development phases that depend on humidity and temperature conditions.

Therefore, as the temperature and humidity inside the silo reach higher levels, the risk of germination, pest propagation, mould growth and fungal development will also be higher. Ultimately, this will lead to the deterioration of grain quality.

Let’s not forget that grain is an excellent insulator due to its very low heat transmission coefficient. When immobile, it maintains the temperature remarkably well: released heat is kept inside the silo. If grain is stored at a high temperature and then left undisturbed, this causes convection flows resulting in hot spots and the condensation of humidity, creating an ideal condition for harmful organisms to reproduce.

The greater the temperature differential (the difference between the temperature of the grain and the external temperature), the stronger these convection flows will be, and consequently the effect of heating and condensation on the grain will be more hazardous.

The temperature probes implemented in Prado Silos’ projects consist of a smooth, flexible and small-diameter tube which reduces the traction on the silo roof. The sensor cable measures the temperature on different levels by several calibrated sensors, in order to provide accurate information for each area of the silo. The sensor cable is easy to extract and to reinsert, thus facilitating any repair, verification or calibrating intervention, even when the silo is full of grain.

The balanced distribution of sensors over the entire volume of the silo is particularly important to provide real-time and accurate information on the actual conditions of all internal areas of the structure. In this way, possible hot spots can be detected and the necessary corrective measures are implemented with optimised response times.

The distribution of the probes must also be adjusted to the design of the silo roof. Excessive and focalised pressure generated by the tension of the probes on the roof can potentially cause serious damage on the silo if structures and supports are not properly dimensioned.

When combined with other types of data provided by a weather station or external monitoring systems, for example, a control software processes the information and launches the appropriate actions: silo ventilation, alarm, notification signal sent to a mobile app that allows remote management of operations… In short, the Prado Silos monitoring systems ensure time and money savings by controlling the temperature and humidity of the stored grain. For further information, please contact us at info@pradosilos.com