A race against time begins to prevent the grain from deteriorating after harvest. In order to maintain an optimal product quality, it is important to take into account the cleanliness, temperature and humidity of the grain to ensure safe and durable storage. In many cases, drying and cooling of the product are not enough to guarantee its good condition. To store grains in places with more extreme climates, we can take measures and add new protections that help us achieve a correct storage in the steel silo.

Although cold temperatures present fewer problems for grain management, excessively low temperatures can lead to breakage of the kernels and significant losses. However, it is in tropical settings where high temperatures and humid environments pose the greatest challenges: these conditions are prefect for the grain to start its natural, biological processes, and germinate. In addition, high temperature and humidity perfect conditions for the emergence and propagation of fungi, micro-organisms, insects or mites.

In addition, sudden temperature variations can lead to other problems such as condensation and moisture migration between the product, which translates into serious damage to the grain and quality differences within the same silo, affecting the entire storage. Condensation can occur in any climate – a couple of degrees temperature difference between the outside and the inside of the silo can suppose a risk of condensation at dew point, creating crusts and other damages on the upper level.

For a proper grain storage, the three parameters to manage are temperature, humidity, and time of storage. Keeping these values right is the best way to avoid loses and damages to the grain.

To prevent crop loss due to these factors, we rely on ventilation and temperature control systems to help us monitor, control and maintain the temperature required inside the steel silo. These control systems give us the information and the mechanisms to take action against undesirable conditions inside the silo, but they require energy and constant attention to the installation.

There are also other systems that will allow us, passively and without additional operating or energy costs, to maintain optimum temperature and humidity conditions: silo insulation.

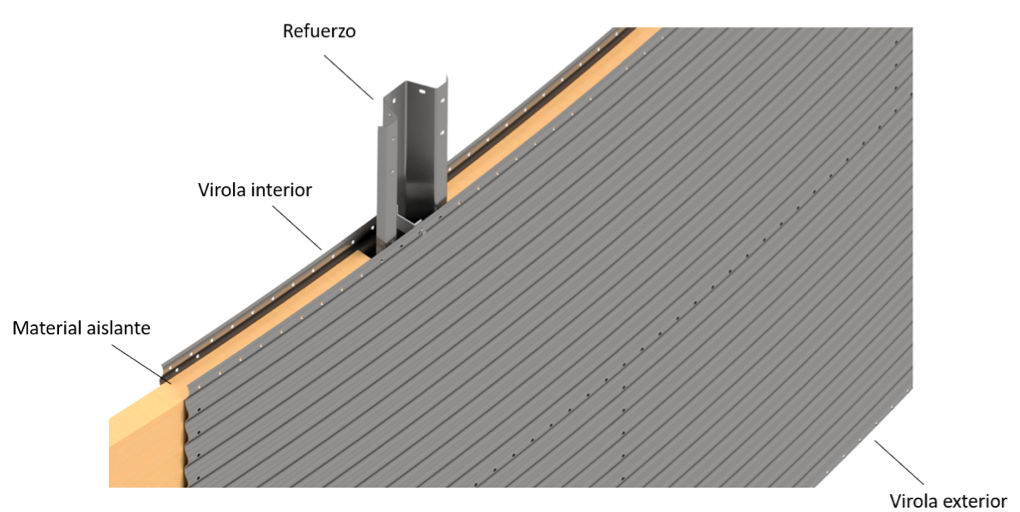

Thanks to the galvanised silo design, with its arrangement of external stiffener on walls and waved roofs, it is possible to install an external sheet that creates an air chamber in the steel silo between the external layer and the internal part that is in contact with the grain. These chambers can be created in the silo cylinder as well as in the roof and hopper, in the case of elevated hopper silos. In this way, we avoid direct sun radiation on the silo wall (which can have a particular impact for some products, such as paddy rice or malt) and create additional protection against temperature changes.

In addition, the space created between the inner and outer sheets of the silo can be fitted with specific insulation materials, such as mineral wool or insulating foams. There are various combinations, and insulation can be installed in the entire silo structure, only in the cylinder, or only in the roof. With this addition, depending on the material used, high levels of thermal resistance can be achieved, extending the storage period in the silo and reducing the costs of the operation.

In the case of hopper silos, there is also the possibility of being able to install a sheet metal lining on the supporting structure of the conical silos. This cladding around the legs prevents the grain stored in the hopper (up to 300m3 in the larger models) from being exposed.

Another passive insulation system is painting. A storage silo with a white paint coating prevents heat absorption and thus avoids solar radiation. There are also special ceramic paints that provide a very high thermal resistance due to their composition.

Insulation thus becomes a great support for grain management in galvanised silos. It helps us to maintain the right temperature for longer, reducing the use of active control systems, such as fans or coolers, and helps us to save on energy consumption.